Quality Control

Quality Assurance

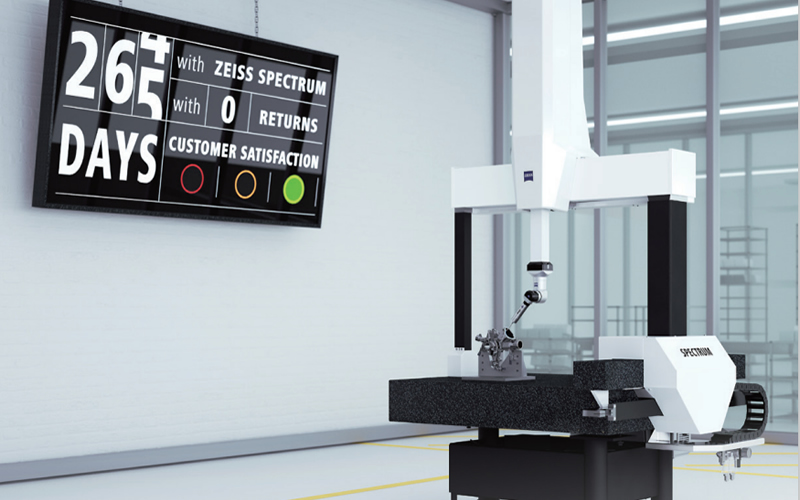

Quality assurance at Hitop Mold is an integral part of our daily activities; and is our top priority. Our quality program is comprehensive and is coordinated across all manufacturing disciplines. Every employee of Hitop Mold is held accountable for monitoring and improving quality.

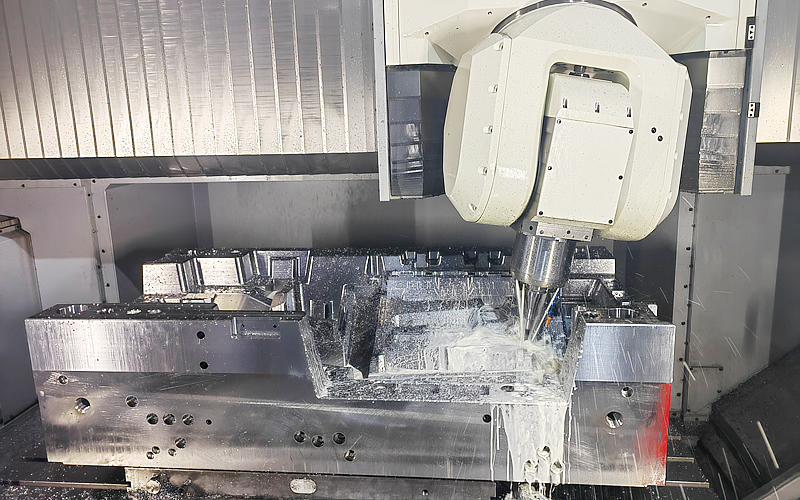

During mold manufacturing, every individual is empowered to take responsibility for fully inspecting the detail on the operation he has performed. As a result, we are able to guarantee that the tolerance on the print will be met 100%, for every working component within the tool.

This underlying philosophy applies to our commitment to our customers. At every stage of your project, from prototyping to production tooling to contract manufacturing, every Hitop Mold employee is focused on exceeding your expectations.

We have a group of QA staffs with professional technology and excellent management experience. We will endeavor to keep improvement and pursue for perfection so as to offer excellent and best service to our customers.

Main QC Procedure:

1. Document and Data Check

2. Design Optimize control

3. Steel Hardness Inspection

4. Electrodes Inspection

5. Core and Cavity Steel Dimension Inspection

6. Pre-Assembly Inspection

7. Trial Report and Samples Inspection

8. Pre-Shipment Final Inspection

9. Mould Package Inspection