Injection Moulding

Injection Moulding

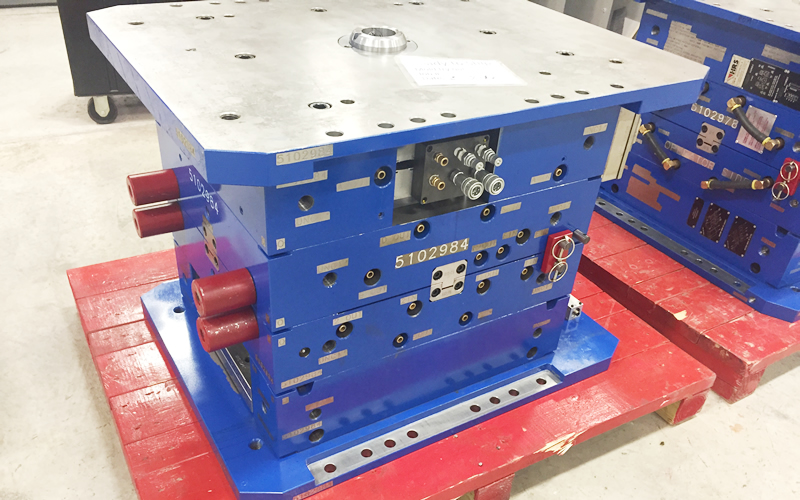

Our ISO 9001:2000 certified molding facility running 3 shifts and 24Hrs/7Days, houses state-of-the-art injection molding machines from 50 to 2800 tons.

More than 30 years' experience in building injection molds for high-volume, fast-cycling applications where molding accuracy is vital to producing high-quality plastic components at the lowest cost per part, enables us to offer contract-molding capability that is second to none.

We have experiences in the following materials:

ABS

PC/ABS

PPO(Noryl)

Polyamide (Nylon)

TPE (Rubber)

Polycarbonate

Polypropylene

Polystyrene

Acetal and some special materials such as PEEK,PPT and Ultem.

Phototyping

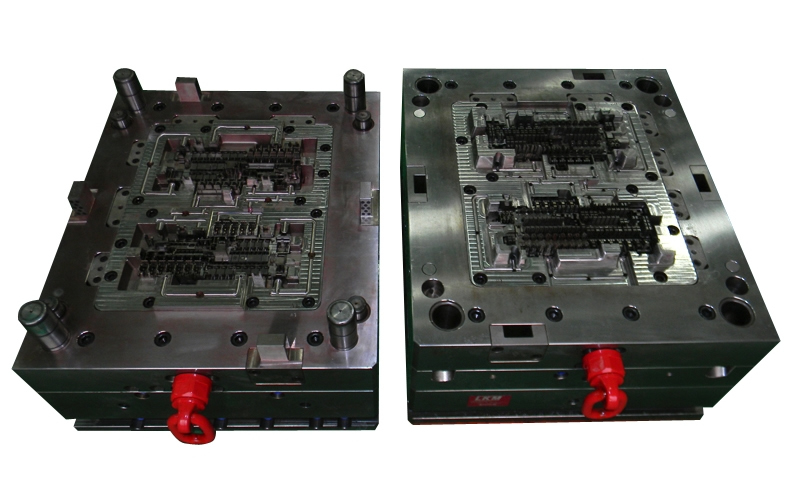

In Hitop Mold, we apply our prototyping expertise to optimize your part design and offer important benefits for your molding program.

our expert prototyping staff offers a wealth of experience meeting aggressive delivery schedules, to ensure the fastest speed to market for your product.

Our prototyping operation includes a fully equipped state-of-the-art molding facility that offers fast turnaround of plastic components, as you refine your part design for manufacturing.

Our experienced program manager will track your entire program from inception to completion. The knowledge gained from the prototype mold and molding process will then be seamlessly applied to the design and manufacture of your production tooling, to eliminate costly delays.