Program Management

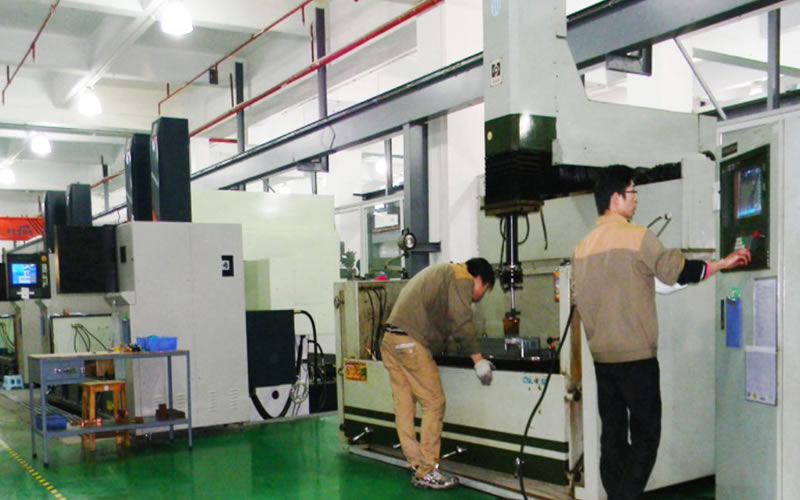

In Hitop Mold, project management plays an important role in the mold building progress. This includes effective scheduling of the workflow, good communication both internally and with the customer and good control of the manufacturing process.

Hitop Mold appoints a Project Manager to each individual project and client. The Project Manager is in charge of the entire project from start to finish providing direct communication for the client. All project teams communicate in English and include qualified engineers.

Daily 30-minutes meeting is held to review the project progress and/or solve some problems occurred due to accident or error. We provide weekly progress reports to customer using Microsoft Project, including photos and videos as necessary.

Project tracking for Mold & Components:

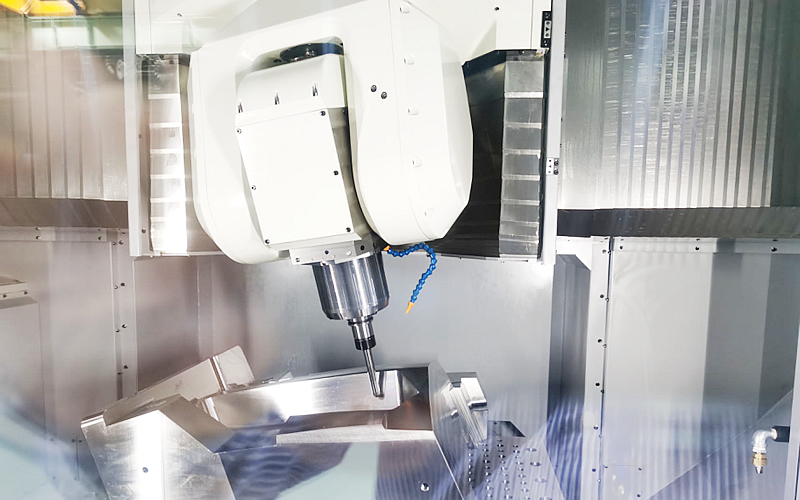

1. Receive and file data from customer

2. Make record for each project&release data to design dept.

3. Hold a meeting & discuss before design begins

4. Get the drawing approved by customer

5. Arrange mold manufacture

6. Actual mold progress checkup and report

7. Discuss with client for each unconfirmed problem

8. Trial sample inspection and Measurement report

9. Clients' approval

10. Arrange shipment or bulk production of mold.

Project tracking for parts production:

1. Receive and file data from customer

2. Make record for each project&release data to molding dept.

3. Mold tryout to see its function and result

4. Hold a meeting & discuss before mass production

5. Get Instruction book done for workers

6. Start production

7. Self-inspection for plastic parts

8. Shipment.

-- Steel Order Information sheet including quantity, size, brand/manufacture, expected delivery time, actual delivery time, etc will be prepared and sent to customer for their reference once material and mold base are ordered.

-- Video movie for First shot will be taken and sent to customer together with sample dispatch to show them the live mold tryout conditions.

-- Molding Process Parameter, including machine tonnage, injection pressure, cycle time, etc will be provided once after mold tryout.